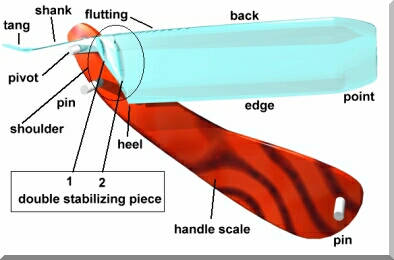

Razor parts

The straight razor consists of a handle and a blade. The handle

consists of two shells, bridged by three pins. One of the pins is

the pivot between the handle and the blade. The blade has an

integrated tang. The transverse furrows on the top of the tang are

called fluting or flutting and originally served to improve the

grip. The blade and tang often contain engravings or etchings,

indicating size and brand.

The stabilizing piece resists against torsion. It can be single, double, or single ellipsoid, depending on blade style, type, and esthetics.

Blades are made of normal steel with a carbon-content of 0.6% or more, and of rust-resistant chromium-steel. Carbon steel is easier to sharpen but more brittle, liable to chipping off and staining. Stain-resistant steel takes longer honing, but the results hold longer, and the edge is less vulnerable. Handles are made of Ambonia, Celluloid, Bone, Pakkawood, Mother of pearl, Ebony, Buffalo horn, Plastic. Celluloid is flammable and spontaneous inflammation has been described at higher natural temperatures. Even now, celluloid production is associated with extreme safety measures. Buffalo Horn can deformate after some time, increasing the risk of edge damage when closing the knife: it has form memory, but for the wrong form. Mother of pearl is brittle, which might result in cracks soon. Plastic is very thin and easy to deform, causing increased risk that the edge touches the handle while closing it. The hardwood handles do not rot because they are highly impregnated with resins; the weight gives ideal balance. Bone is stable as well. Both packawood, snakewood, and bone have the best material properties for intensive use.

The razorblade must be guided while closing, because all handles

may loose their form a little after some time, which is normal.